Description

Keep audio signals clean and unaltered with AudioQuest Rocket 22. The carefully finessed blend of Perfect-Surface Copper (PSC) and Long-Grain Copper (LGC) is packed in a semi-solid concentric pattern with reversing spiral forms to keep wire position and contact optimal for minimum signal distortion.

Launched alongside the Rocket 11, the Rocket 22 improves on the Rocket 11’s award-winning formula by increasing the gauge of conductors, lowering it’s impedance and combining AudioQuest’s Long-Grain Copper (LGC) with Perfect-Surface Copper (PSC). All of these adjustments mean the Rocket 22 offers improved clarity, reduced harshness and superior bass-to-treble frequency extension while remaining affordable. The SureGrip 100 and 300 plugs are the perfect compliment to the Rocket 22 by utlising direct-silver/gold plating compared to the distortion-casuing nickel commonly found in standard banana plugs.

The AudioQuest Rocket series is one of the most successful AudioQuest speaker cables due to its excellent design and construction. The Rocket series is an ideal speaker cable for entry to mid-level range Hi-Fi and AV systems. This latest cable in the Rocket series, is constructed from a mix of the award-winning AudioQuest FLX/SLiP 14/4 and AudioQuest Rocket 33 speaker cables.

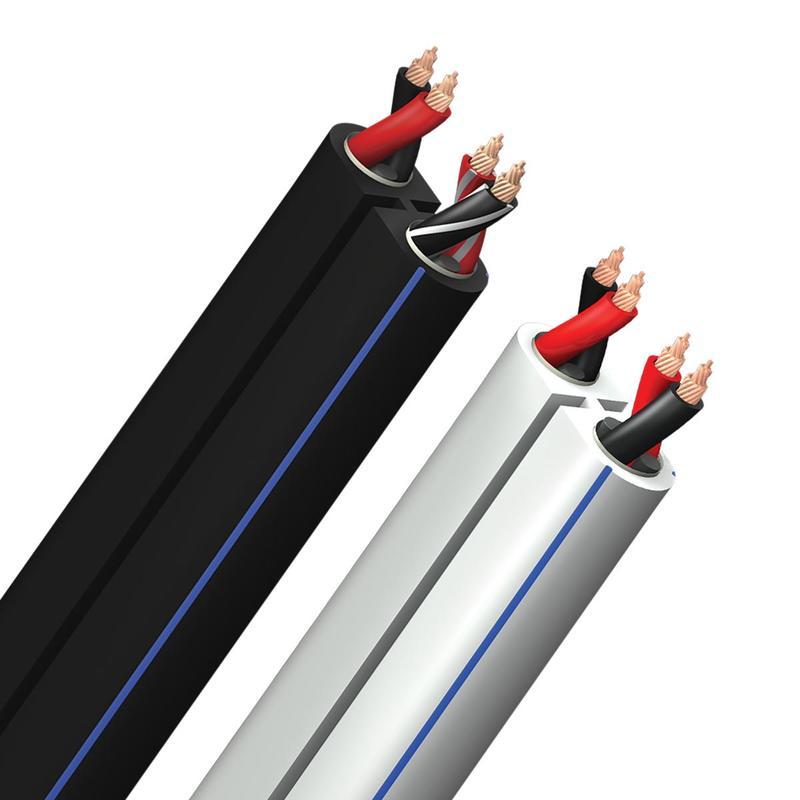

The Rocket 22 speaker cable utilises both ‘Long-Grain Copper’ and ‘Perfect-Surface Copper’ semi-solid true-concentric conductors, a first for AudioQuest. The combination of ‘Long-Grain Copper’, ‘Perfect-Surface Copper’ and true-concentric conductors ensures the Rocket 22 delivers a more balanced, dynamic and cleaner sound. Rocket 22 is available as both single wire and biwire configuration.

A clearly audible step up from Rocket 11, Rocket 22 is a high-performance, low-noise, CL3/FT4-certified cable designed to quickly and easily accommodate either Full-Range or Single-BiWire applications, making it an outstanding choice for custom installers and enthusiasts alike. With no breakouts, pants, or braids to cut back and dress, preparation is as simple as can be.

“True-Concentric” is an industry standard term for when each layer of strands in a concentric conductor is spiraled in the opposite direction from the layer below, eliminating the lines of contact between the layers, and increasing contact pressure at the points of contact. The downside is much more machine time and higher cost – the upside is better sound you can hear. True-Concentric construction significantly furthers the beneficial effect of the skin-effect by dramatically increasing layer autonomy.